Metal & Ceramic Solutions with ZYYX MC

ZYYX Labs supplies complete solutions for cost-efficient 3D printing materials with unique features, optimized for different desired properties and applications.

ZYYX Metal & Ceramic Solution

We are selling a complete solution for manufacturing metal or ceramic parts with the ZYYX printers all by yourself. Perfect where you don’t want to send your sensitive model files, drawings, or parts to an external company or potential competitor.

These types of materials have 3-4 times higher temperature resistance than plastics and also have much higher wear resistance.

The interesting thing is that a complete solution from ZYYX is a very cost-efficient solution compared to similar systems on the market!

The process system consists of three parts as well as the new filament materials. You can read more about the metal and ceramic filaments here.

The Metal & Ceramics Material and the Process Solution

The filaments consist of some useful material (ceramic or metal powder) mixed with a plastic carrier, so that the filament can be printed in a 3D printer. This plastic is then removed, so you get a part entirely in the useful material.

In theory there are thre steps in the process:

1. Model production – The resulting parts are called green bodies.

2. Debinding (removal of binder/carrier) – The resulting parts are called brown bodies.

3. Sintering – The resulting parts are called sintered or finished bodies.

To get better results, step 2 is sometimes divided into two processes:

2A. Chemical debinding

2B. Thermal debinding

So in practice there are 4 steps performed with 3 units. The three units are described right and below.

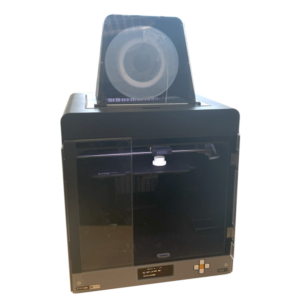

Unit 1 – ZYYX Pro II MC

ZYYX Pro II MC – A 3D printer optimized to also print metal and ceramic filaments. See examples below. There are also upgrade kits for older printers.

With the 3D Printer you do step 1 of the process to create green bodies.

Below you see a picture of the ZYYX Pro II MC unit.

See more details in the web shop.

Unit 2 – Chemical Debinding Unit

The Chemical Debinding Unit is s piece of equipment to chemically remove the plastic material from the green body, also called debinding. This is step 2A of the process, and it is performed by soaking the green part in Acetone which is heated to 40 0 °C. The time this process takes depends on the material, but somewhere between 2 and 24 hours. After that step and drying, you get an (almost) brown body.

Below you see a picture of the Debinding unit.

See more details in the web shop.

Unit 3 – Sintering Furnace

A sintering furnace. Here there are different models depending on the material you want to work with, since they have different requirements.

With this oven, you usually do two process steps.

Step 2B. Thermal debinding

First, thermal debinding, burning off the last remnants of the plastic carrier, this is done at 500-650 °C.

After that step, you have a brown body.

Step 3. Sintering

The material is then sintered/burned at a higher temperature. This temperature depends on the material, but is generally between 1200 and 1550 °C. For metals this needs to be taking place in a non-oxidizing atmosphere, or the metals will oxidize and loose their quality. This means that the furnace for metal is a bit more complex. The ceramamics can be sintered in open furnaces which usually is easier.

The heating process takes around 1-2 days and after cooling you then have a complete part in the selected material.

Example printing in aluminum oxide:

Below you can see our line of different furnaces.

Sintering Furnaces

Metal & Ceramic Sintering Furnace

ZX161 is a tubular furnace for sintering ceramics in ambient air, and metal parts under inert atmosphere.

Maximum temperature is 1600 °C and power is 6 kW.

Chamber: inner tube diameter is 10 cm and 20 cm useful length.

Materials: Porcelain, Alumina, White/Black Zirconia, H13 tool steel, 316L Stainless steel (using Argon or N2 gas)

More details in web shop: ZX161 Tubular Sintering Furnace for Metals and Ceramics.

Large Ceramic Sintering Furnace

ZX162 is a large furnace for sintering ceramics in ambient air.

Maximum temperature is 1600 °C and power is 18 kW.

Chamber: 250x200x250 mm

Materials: Porcelain, Alumina, White and Black Zirconia

More details in web shop: ZX162 Large Sintering Furnace for Ceramics.

Compact Ceramic Sintering Furnace

ZX163 is a compact furnace for sintering ceramics in ambient air.

Maximum temperature is 1600 °C and power is 6 kW.

Chamber: 200x120x150 mm

Materials: Porcelain, Alumina, White and Black Zirconia

More details in web shop: ZX163 Compact Sintering Furnace for Ceramics.

Porceline Sintering Kiln

ZX163 is a large kiln for sintering porcelain in ambient air.

Maximum temperature is 1320 °C and power is 4.5 kW.

Chamber: 360x360x360 mm

Materials: Porcelain

More details in web shop: ZX164 Sintering Kiln for Porcelain.

ZYYX Complete Kits for Metal & Ceramic Production

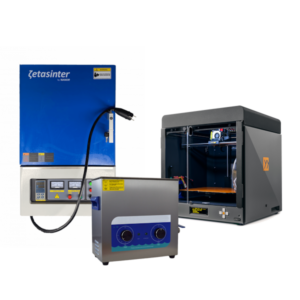

ZYYX Metal & Ceramic Complete Kit

Complete package for metal and ceramic 3D printing.

More details in web shop: ZX171 ZYYX Metal & Ceramic Kit.

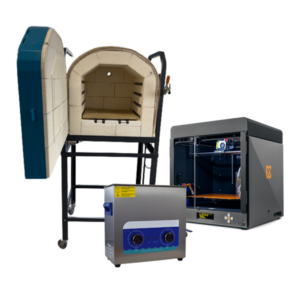

ZYYX Ceramic Large Complete Kit

Complete package for large ceramic 3D printing.

More details in web shop: ZX172 ZYYX Large Ceramic Kit.

ZYYX Ceramic Compact Complete Kit

Complete package for compact ceramic 3D printing.

More details in web shop: ZX173 ZYYX Compact Ceramic Kit.

ZYYX Porcelain Complete Kit

Complete package for large porcelain 3D printing.

More details in web shop: ZX174 ZYYX Porcelain Kit.