Description

Widely used in the ceramic field, alumina is a wear resistant material. Zetamix Alumina can resist extreme temperature and it used to produce parts like a burners, venturi tubes, and other high temperature parts. Because it is an inert material, it is both a good thermal conductor and a good electrical insulator.

Advantages:

- High density

- High mechanical strength and hardness

- Thermal stability and resistance to wear

- Chemically inert

Net weight

0.5 kg

Colour

Natural light grey

Printer Compatibility

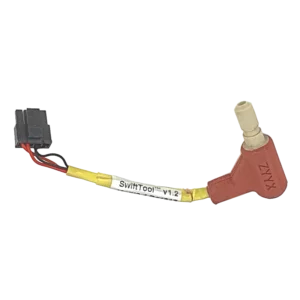

ZYYX Pro II: with Metal and Ceramic Kit

ZYYX Pro: No

ZYYX+: No

ZYYX Classic: No

Ease-of-Print

3/5

Filament Storage

It is very important to protect the filament from moisture and moist air to keep the print quality. Always store the filament in the heated chamber, vacuum sealed (with desiccant), or in a dry-box.

1. Print Settings

Select ZYYX Alumina in Simplify3D. The model needs to be scaled up to 126.6% in x+y and 129.9% in z to compensate for sintering shrinkage.

If used with other printers, we recommend

2. Chemical Debinding

24 hours in an acetone bath at 40 °C (it depends on the geometry of the part), stop the heat a couple of hours before removing it from the bath (when the mass loss over 5%).

Finally 2 hours drying in ambient atmosphere.

3. Thermal Debinding

Heating from 50 °C to 500 °C with an 8 °C/h ramp, 2 hours holding time.

4. Sintering

In a high temperature furnace with air atmosphere, heating up to 1550 °C with a 50 °C/h ramp. 2 hours holding time. Cooling 100 °C/h.

Technical datasheet

See Brochures & Data Sheets

Safety datasheet (SDS)

See Brochures & Data Sheets