When testing various flexible plastic filaments, we have seen that the softest of them, such as Ninjaflex, have a tendency to creep out of the extruder when extrusion speed is increased. After an analysis of this scenario, we discovered that a major cause of the creep is the spring-loaded arm compressing the filament to such degree that its trajectory is curved.

Since we have an extruder with open architecture, we decided to test simply putting a softer spring in place. This produced such positive results that we have decided to release the soft spring as an accessory.

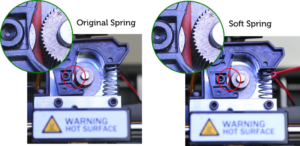

In these two pictures you can see that the soft spring does not bend the filament, making extrusion of soft filament more reliable and enabling higher speeds.

The Soft Spring is installed by removing the front fan and using the Spring removal tool to put the spring in place. We have added a red marker to ensure our users remember to change back to the original spring in order to reliably print other types of filament!

Printing tips

As a starting point, you should use the predefined ZYYX TPE/proFlex Material setting in Simplify3D. This will work for most types of flexible filaments. Most important is to print slowly and with the correct temperature. Even with the Soft Spring, if you print too fast or at too low a temperature, the extruder can still jam, causing soft filament to creep out of the side.

Before loading a soft filament, it is extremely important to ensure the extruder is in good condition. This can be done by performing a couple cleaning cycles with our Extruder Maintenance Kit.

When loading the filament, ensure you have preheat set to at least 230 degrees, otherwise the filament might creep out while loading. If you fail to load the filament, try to perform a nozzle cleaning sequence to ensure the nozzle is absolutely clean.

Some stringiness will occur in the prints. This can, in some cases, be reduced with a retraction at slower speed – around 400 mm/min.

By printing small test objects you can fine-tune the surface finish by lowering temperatures, but in this case you must monitor the print closely and cancel if you see indications of jamming or filament creep.

Examples

ZYYX Vase printed in vase mode with NinjaFlex

ZYYX Robots

ZYYX Ball, printed in TPU.

Model at http://www.thingiverse.com/thing:996962.

Palmiga Innovations Sandal, printed in Palmiga innovation conductive TPU.

Model at http://www.thingiverse.com/thing:429902

Open RC Tire, printed in NinjaFlex

Model at http://www.thingiverse.com/thing:240970

ZYYX Robot, printed in NinjaFlex.

Model at http://www.thingiverse.com/thing:996894

You can purchase the Soft Spring and spring removal tool in our webshop.