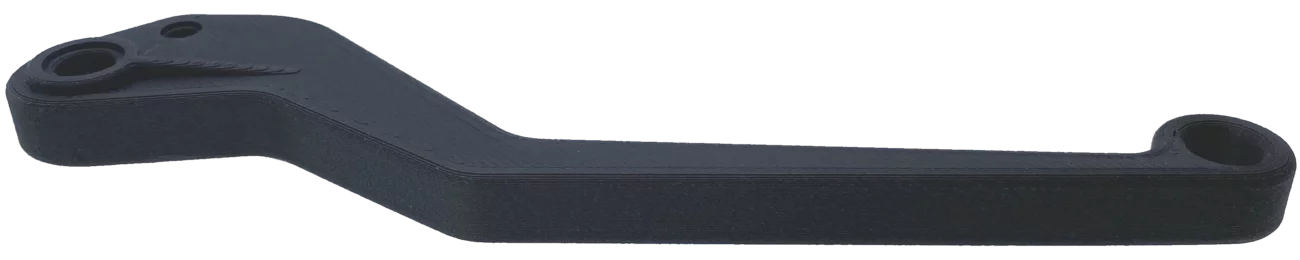

– A carbon fiber master

The ZYYX Pro II is an exceptionally quiet industrial-grade 3D printer for functional prototypes and high-strength parts.

It has a closed design and clean room class air filtering system, perfectly suited for every office, classroom, makerspace, or workshop.

The ZYYX Pro II is developed to be:

- Robust and reliable

- Clean-air safe and fume-free

- Quiet by design

- Easy to use with a MagFlex™ build-plate system

- Compatible with Engineering Grade materials

- Protective of material quality and strength even during storage

- Accessible on-line for control or monitoring

- Sustainably delivering professional print quality

OfficeSafe Ultra™ – Clean and Fume-free Air

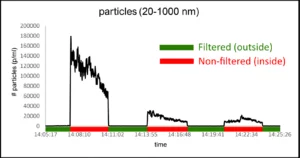

Workplace health is of highest priority and the ZYYX Pro II is designed to be perfectly safe for the office desktop. Our new filtering system, a Swedish-made combined HEPA H13 and active carbon filter, removes more than 99.95% of the ultrafine particles, volatile organic compounds, and odors that are created in the air from melting polymers. This innovative, 95 mm thick filter of clean-room class is so efficient that it even cleans the air of the room.

Below to the right you can see a graph of the amount of particles inside and outside of the printer when printing ABS. This measurement was done with a prototype filter that absorbs somewhat less (~99 %) of the particles.

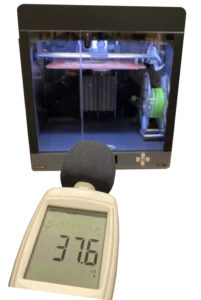

OfficeSafe Whisper™ – Quiet by Design

While designing ZYYX Pro II we tested dozens of power-supplies. They were all found to be noisy, often due to cooling fans suddenly flipping on and off or small whining fans. So, we decided to do our own cooling solution together with a 500 W passive power-supply. That made a huge difference. The ZYYX Pro II PSU is virtually silent.

For filters and cooling we used large fans from Noctua and Arctic, famous for their low-noise design in the gaming PC area. The result is a whisper level 3D printer with a 38 dB(A) sound level while printing with all heating functions active.

The ZYYX MagFlex™ Build-Plate – Easy to Use

The new ZYYX MagFlex™ spring steel build-plates make removal of prints easy to do by hand. The 3D printer bottom glass platform, adapted with steering pins for easy positioning of the build-plate, is covered with a magnetic layer. Due to the steering pins, the build-plate is swiftly positioned accurately on the glass platform and attaches firmly by magnetic force.

After printing, the build-plate is lifted from the glass base after which the print is removed from the build-plate by bending the plate. The build-plates are available with three different top layers adopted for different print materials.

Below you can see a demo video.

proTect™ – Protective and Reliable

The ZYYX Pro II comes with the proTect™ system that has been developed to maximize filament durability during storage. The filament is kept in a resealable vacuum bag with a dehumidifier capsule. Vacuum is accomplished with an electrical vacuum pump (included). The dehumidifier capsule changes color if it is exposed to moisture, signaling if extra drying of the filament is needed before use which avoids failed prints and saves time and material. During printing, the filament is taken out of the bag and kept dry inside the heated print chamber.

Other ZYYX Pro II Features

Robust Design

- All-metal structural design giving stability and quality for prints

- Thick and stable aluminum top plate with linear rails

- Heat insulated cover and see-through service top door

- OLED screen with high contrast and readability

Controlled printing environment

- Heated chamber – provides a consitent printing environment tuned to the chosen material, securing layer adhesion and preventing warp. A heated chamber is necessary for some high-strength engineering grade materials

- Chamber temperature up to 75 °C. Heats chamber to 65 °C in 5 minutes

- Automatic Leveling – auto-calibrates the distance between the nozzle and build-plate for every print, compensating for any tilting of the build-plate

- Material Monitor – auto-pauses the print during filament run-out or tangling

Unique extrution system

- Dual-sided large gear extruder (Bondtech LGX) with support for high-temp printing

- Supports SwiftTool24™ – quickest system for nozzle change on the market, up to 275 °C (and coming SwiftTool24™ up to 450 °C)

Versatile software use

- Simplify3D, the market leading software, is included

- Open-material system – No limitations, you decide

- Off-grid or Online – Your choice

- CyberSafe – can be used stand-alone – no computer/internet needed during printing

- Remote access Ethernet module with optional camera

- Enhanced profiles showing user settings before start which minimizes the risk for defective prints

ZYYX Pro II Technical Specification

Print technology Fused Filament Fabrication (FFF)

Product weight 25.5 kg

Product size (BWD, mm) 441 x 465 x 457 mm (536 incl. filter)

Build volume 285 x 235 x 210 mm

Printing (extruder) temperature 100 – 275 °C

Chamber temperature Room temp to 75 °C. Heats chamber to 65 °C in 5 minutes

Stepper motor Type 1.8° step angle, 1/256 micro stepping using silent Trinamic TMC2209 stepper drivers

Max resolution 50 µm layer thickness, 11 µm XY positioning

Speed Up to 200 mm/s print speed

Build-plate MagFlex™ Glass build-plate with removable magnetic spring sheet and ZYYX 3D print-sheet top layers (Pro TL, Multi-Material TL, Perforated TL)

Extruder Dual-sided large gear extruder (Bondtech LGX) with support for high-temp printing

Nozzle system for basic materials SwiftTool24™ Multi 0.2 mm

Nozzle system for abrasive and basic materials SwiftTool24™ Carbon 0.4, 0.6, 1.2 mm

Filament diameter 1.75 mm

Filament materials used with the MagFlex™ Pro TL ZYYX proNylon, ZYYX proCarbon, ZYYX proGlass

Filament materials used with MagFlex™ Multi-Material TL ZYYX PLA, ZYYX Flex, ZYYX PETG, ZYYX PETG-CF, many third party filaments

Filament materials used with MagFlex™ Perforated TL ZYYX ASA, ZYYX ABS, third party filaments with significant shrinkage

Interfaces SD Card, USB for firmware updates, Ethernet

Firmware Custom Sailfish Open Source

Network Web interface with optional camera

Desktop Software Simplify3D

Minimum computer requirements (for data preparation) Intel Pentium 4 or higher processor, 4 GB of RAM, Windows 7 or later (32- or 64-bit), MacOS X 10.7 or later, Ubuntu Linux 14.04 LTS or later. OpenGL 2.0 capable system, Internet connection

Recommended computer requirements Intel Core i7 or better CPU, 8 GB or more of RAM

Supported import file types STL, X3G, 3MF

ZYYX Pro II Engineering Materials

The ZYYX user can choose from a line of carefully selected high-quality filaments thatcomes with associated plug-and-play filament profiles. This allows the professional user to concentrate on their creations, rather than tweaking print parameters.

ZYYX proCarbon™

ZYYX proCarbon (Carbon fiber reinforced polyamide) is a material with high stiffness and high tensile strength. It is ideal for functional prototypes that are exposed to tough environments, as well as end use parts such as jigs and fixtures in a production setup.

The ZYYX proCarbon must be printed with the hard-coated SwiftTool™ (Carbon0.4, Carbon0.6, or Carbon1.2), since this abrasive material will wear-down or degrade other SwiftTools. For full technical data on our filaments, please see the page Data Sheets.

Do you want to take a closer look at the material? Don’t hesitate to place an order for a carabiner sample at our sample page above.

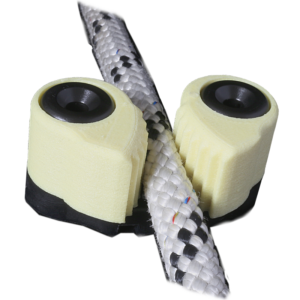

ZYYX proNylon™

ZYYX proNylon (Polyamide) is a material for use where low friction and flexible yet strong parts are needed. It is also resistant to most chemicals. Ideal applications range from bushings and pulleys to electronics casings where resistance to the environment is a priority.

ZYYX proGlass™

ZYYX proGlass (Glass-fiber reinforced polyamide) has a very high tensile strength-to-weight ratio, and is less electrically conductive than the ZYYX proCarbon. It is ideal when you need parts that are resistant to impact, or as an alternative to proCarbon where electrical insulation is required. For many users it can be an alternative to ABS, offering better temperature resistance, better layer adhesion, and higher strength.

ZYYX proGlass is also abrasive and must be printed with the hard-coated SwiftTool™ Carbon0.4, Carbon0.6, or Carbon1.2.

Included with ZYYX Pro II 3D Printer

Pro II MagFlex™ Build-Plate with top layers Pro TL, Multi-Material TL, Perforated TL

SwiftTool24™ Carbon hardened tool head 0.4 mm

SwiftTool24™ Carbon hardened tool head 0.6 mm

ZYYX Connect (remote control interface)

Simplify3D license

proTect™ filament storage system

Pro Maintenance Kit

Tool Box

1 kg ZYYX proCarbon filament

1 kg ZYYX proNylon filament

1 kg ZYYX PLA filament

1 kg ZYYX ASA filament

1 kg ZYYX PETG filament

1 kg ZYYX Flex95A filament

(Basic package also available)

Pricing and Purchase

You can check the ZYYX Pro II 3D Printer package prices and availability in the store:

ZYYX Pro II™ 3D Printer kit

ZYYX Pro II™ Basic 3D Printer kit